OCA, Optical and Tape Bonding

Bonding Integration for LCD Ruggedization

Bonding is popular among industry segments that are prone to harsh environmental conditions, such as military, marine, medical and transportation applications.

When integrating or upgrading LCD designs, it is important to consider ruggedization method to provide extended lifecycle and enhanced viewability. When you add bonding to your design, the display increases in impact resistant and is less prone to environmental vulnerabilities like dust collection and moisture condensation.

Standard applications for bonding include touchscreen, small handheld screens and large display screens. Why add bonding? It acts as a method of integration for other LCD components. For example, in order to secure a touchscreen or coverglass to the display, a bonding method might be recommended. Bonding is mostly helpful in direct sunlight situations, where you need to reduce reflection and increase ruggedization. Other common reasons to perform a bond to your LCD include when a touchscreen or coverglass has been broken and/or needs to be integrated into your LCD design. You can read more about our coverglass substrate options by clicking here.

AGDisplays offers three different methods of bonding for your LCD: optical bond, OCA bond and tape/perimeter bond. Depending on your application environment, we customize the solution that creates the ideal LCD stack-up to withstand regular usage.

Bonding methods are performed in one of AGDisplays’ Class 1000 clean rooms. Clean rooms are used across various industries where tiny contamination particles may be susceptible for intrusion in the manufacturing process. It is a controlled environment that is specifically designed to keep levels of air pollutants very low. AGDisplays performs our critical manufacturing processes in clean rooms, including our bonding services.

Get A Quote

What is LCD Optical Bonding?

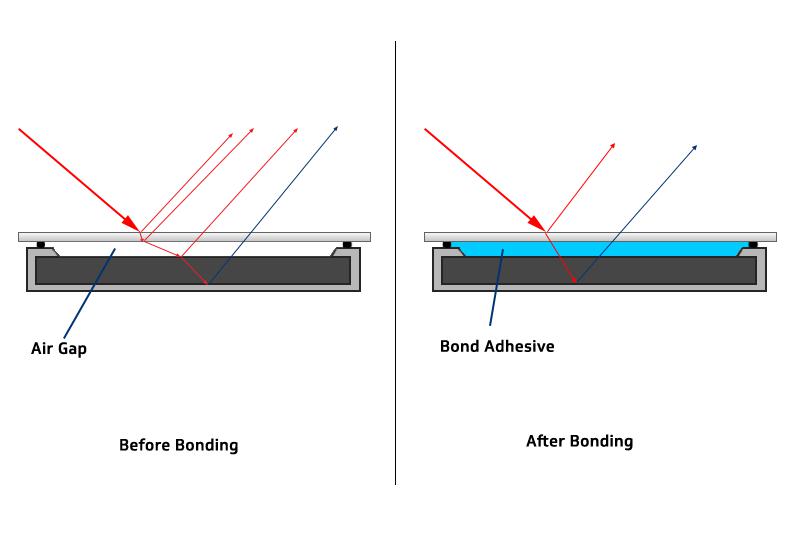

An LCD is made of a stack up of various types of materials that create and enhance certain optical properties of the LCD. Often, LCD designs that incorporate additional hardware to the LCD, such as touchscreens or front cover glass, are constructed in such a fashion that air gaps are left between the layers of its components.

Excessive internal light reflections are created by the air gap which brings optical quality down. This simply means that there are more surfaces for light to bounce through and around, creating a severly reduced quality of contrast and image sharpness. The gap also leaves room for excessive condensation and dirt to compile in that space, creating fog and decreasing screen visibility.

There are various bonding methods, each with unique features and qualities. A liquid optical bond involves an optically clear epoxy that is hardened to create ruggedization and promote enhanced clarity.

AGDisplays follows a simple process to leverage the benefits of our optical bonding. We start with an open LCD stack-up. Our trained technicians manually pour the epoxy onto the LCD and skillfully cover the epoxy with the next design layer (which varies from design to design). This stack-up with then be cured, producing a solid epoxy finish. The layer acts to eliminate the air gap, and the optical qualities of the dried epoxy enhances LCD definition and optical clarity.

Get A Quote

OCA Bonding

Displays and touch panels are at their best when they perform with highly transparent, low-haze, and UV-resistant features. Adding an optically clear adhesive to your LCD’s stack up promotes these features. Liquid optical bond can prove to be expensive. OCA bonding is considered a safe and effective alternative to the liquid optical bond method. Like liquid clear adhesives, OCA reduces the reflection layers in a panel. There are various advantages to choosing OCA bonding as your preferred integration method. OCA bonding is clean, which eliminates the need to clean up residuals after the bonding process is complete. The process produces high yield and is repairable.

OCA bonding is thin, making it an ideal choice for rigid bonding and small LCD frames. Our OCA adhesives are precisely adjusted to fit LCD panels 12” or smaller. The material is considered a dry film, its pressure-sensitive application allows for precise and unique processing in which it fits into your industrial LCD. Although thin, bonding protects the LCD against environmental factors as well as foreign contaminants and abrasive material. Applications include laminating films to rigid or flexible substrates; laminating together two rigid substrates; bonding touch panels and cover lenses; bonding displays to cover lenses or touch panels.

Our experienced team services each industrial panel model individually to diagnose cover glass irregularities. After ensuring repairability, our professional team uses an advanced optically clear adhesive to fuse the LCD and new cover glass, creating a blemish and scratch-free surface. Our advanced OCA prevents and protects end-user’s industrial panels from further damage due to natural wear and tear.

OCA Bonding Benefits:

- Increased Readability

- Strengthened Durability

- High Adhesion

- UV Protection

- Bare ITO Compatible

- Whitening and Yellowing Resistant

Integrating our OCA solution to your panel will improve the following vulnerabilities:

- Moisture/condensation and debris: will migrate into viewable area, significantly decreasing visibility.

- Weakened structural stability: OCA creates a singular structural unit, which outstands rough environments with ease.

- Lowered optical clarity due to increase in glare layers: the addition of a single piece of glass will create two additional reflective surfaces which trap glare, not only from ambient light but can even produce glare from the actual LCD. Adding an AR film does not match the level of clarity and visibility achieved with OCA bond.

- Decreased brightness and readability: considering the possible debris, moisture and multiple refraction layers, readability and brightness are decreased significantly without OCA.

AGDisplays OCA Capability:

| Substrates | Product Size |

|---|---|

| LCD | 1”-12” (typ) diagonal max |

| Touch Screens | 1”-12” (typ) diagonal max |

| Mobile Devices | Samsung Galaxy S4, S5, Note 3, Note 4, Apple iPhone 6,6+ |

| Glass | 9”x13” max/15” diagonal size |

| Polycarbonate | 9”x13” max/15” diagonal size |

| Transparent Materials | 9”x13” max/15” diagonal size |

| Acrylic | 9”x13” max/15” diagonal size |

| Optical Lenses | 9” max diameter |

More About Optical Bonding

Optical bonding is the process of adjoining the LCD and touchscreen or cover glass together to create a single optical index. Put simply, the air gap between the LCD and the cover glass is eliminated, therefore benefiting the LCD’s optical functionality and reducing the number of reflection points. Creating this singular optical index adds clarity and viewability to the display’s screen. Our bonding is performed with a proprietary adhesive, which is solidified with a quick but reliable curing method.

Why add an optical bond to your display? Besides creating a single optical index, there are other benefits to adding an optical bond to your LCD. Most LCDs have plastic surfaces that are not vandal or weatherproof. This component is called a cover lens. The material does not hold up well against scratches or damages, leaving your LCD with large vulnerabilities. To protect your LCD display, you will need to install a cover glass or other strengthened polycarbonate material to the LCD for protection. Adding this hardened substrate will require a bond. Adding an optical bond improves resistance against shock and vibration, which benefits those using their display in a volatile or rugged environment. Lastly, eliminating the gap prevents dust, moisture and condensation ingression, keeping your LCD readability and clarity at superior levels.

Our optical bonding service is the most robust ruggedized bonding service AGDisplays has to offer. Augmented optical performance including increased luminance, increased contrast, and reduced internal reflections. Optical bonding creates superior LCD strength and prevents a shattering screen and less vulnerable to contamination and moisture. Increase the quality and lifespan of your LCD while keeping replacement costs low with this service. AGDisplays is capable of low and high volume production. Full lamination may include outer substrates consisting of adhesive and elements such as mesh and other optical films.

Our optical bonding method is performed in-house by a skilled technician on any sized LCD. Each LCD is carefully handled throughout the technical process. Quality assurance measures and testing are performed on each LCD to guarantee your specifications are met. We strive to meet the needs of medical, military and other specialty markets and ensure that each product maintains high quality standards.

- Augmented optical performance: increased luminance, increased contrast, reduced internal reflections

- Ruggedization: an optical bond creates superior LCD strength and prevents shattered screens

- Reworkable through production process

- Halogen-free: low toxicity, environmentally-friendly materials

- Excellent UV resistance

- Non-yellowing of materials used in bonding process

- Extended operating temperature range capability

Laminated applications can include:

- EMI shielding: prevent electronic interference

- Privacy filters: control the position from which display can be viewed

- Enhancement filters: add a tint and enhance contrast

- Security screens: shattered glass sticks to this layer rather than scattering

Substrates:

- Fully laminated displays allow a wide range of substrates. The standard options are: glass, polycarbonate and acrylic.

- The appropriate substrate is selected by matching substrate properties to end-use requirements and cost.

Tape Bonding

When optical bonding is not practical for your LCD, AGDisplays offers tape, or perimeter, bonding. Perimeter bonding helps your company save on costs while still ruggedizing your panels sufficiently. Our tape bond services provide a secure bond that increases productivity, long-term durability and improved appearance. The adhesive offers a wide temperature specification, allowing durable placement of the touch screen to the LCD in various environments.

Our technical experts use a class 1000 clean room to manually perform each bond with precision. Manufacturing yield for perimeter bond is high and is a cost-effective & common solution. AGDisplays offers tape perimeter touch screen and shield front perimeter bonding. Consult AGDisplays today to speak with a representative about which option is best for your project. AGDisplays supports virtually any manufacturer of LCD and touchscreen. For cover glass shield protection, AGDisplays can work with your requirements to offer products and glass materials to achieve your exact requirement.

- Retrofitted to All LCDs

- Bond with High Adhesion

- Withstand Static or Dynamic Strength

- Continuous Bond Distributes Stress Over Entire Bond

- Viscoelastic

- Damp Vibration

- Resistant to Extreme Weather

- Seal Against Environmental Conditions

Get A Quote

Related Services