Component Assembly & Integration

Have a sensible approach to building your LCD bill of materials (BOM) by employing AGDisplays to custom tailor a fulfillment solution to meet your needs. Utilize complete BOM purchasing power while avoiding the headache of managing LCD pairing and procurement activity.

Adding a partner for LCD assembly and kitting not only saves time but it also decreases costs. Your company may not be aware of the actual cost of carrying inventory. When you calculate the cost of inventory storage, damage/theft, handling, obsolescence, and warehouse space, costs can be as high as 30% of the inventory’s value per year.

With our Component Assembly service, LCD and peripherals are custom designed to your needs. We have the unique expertise to custom design your unit and pair safe components. On top of assembly, we offer a range of custom add on solutions such as touch sensor integration, LED upgrades and cover glass solutions.

AGDisplays offers LCD enhancements that are aimed to increase the durability and the functionality of your LCD panel in the environment it will be operating in. Our production team is constantly monitoring production development to be sure our processes are current. Having reliable and up-to-date equipment, processes, and experience needed for each type of integration service reduces fallout, downtime, and overall customer costs.

AGDisplays offers integration services to its customers utilizing our modern facilities that include the following equipment:

- Multiple state-of-the-art Class 1,000+ clean rooms with integrated assembly lines

- Team with 25+ years of Technician and Repair Experience

- Two Oven Chambers

- Environmental Test Chamber

- Five Lines of OCA Equipment

- ESD Controlled Production Floor

- Radiometer/Photometer

- Laminating Equipment

- De-laminating Equipment

- Universal LCD Test Equipment

Component integration may consist of multiple levels. AGDisplays can design an optical solution to produce your envisioned result and also integrate all the needed components. For integration services needed on projects that are already designed, AGDisplays can follow your predetermined specifications and produce the needed product in a timely and efficient manner. Using our multiple layered procurement strategies AGDisplays can often source your components and reduce the budgeted cost for your LCD related items as well. Alternatively, our team works side-by-side with you in order to customize your LCD solutions to build an LCD specialized to your design build.

Offering our multitude of LCD related, value added services, allows AGDisplays to meet nearly any LCD based need, resulting in a one stop shop for our customers. Reducing the amount of third-party suppliers offers easier communication, reliability, and freight cost reductions.

AGDisplays sources unique LED controllers to accommodate advancing LED technology:

- High output, low power consumption

- Wide adjustable input range

- Dimming ability

- Constant current

- Accommodates NVIS dual mode solution

LCD, Displays & Touch Panels

- Custom LCD/LED backlight displays

- Sunlight readable displays

- LCD Controller cards. NTSC, PAL, QVGA, VGA, SVGA & XGA

- Small and large TFT displays

- Touch panels (resistive and capacitive)

- Inverters (DC to AC)

- Industrial and military ruggedized displays

- Direct OEM replacements available

- Value Added

- Development Kits

Cable & Harnesses

- Assembled cables

- Small assemblies

- Discrete and multi-conductor assemblies

- LVDS, eDP, TTL, USB, Inverter/Power/LED Driver

- FPC/FFC, Touchscreen, Micro Coax

- FPC (Flexible Printed Circuits)

- Micro Coax (ACES, IPEX, JAE)

- FFC (Flat Flexible Cable)

- FFC/FPC to Round Wire

- FPDI-1/VESA TYPE/DF9

- Open-End/Flying Leads

- Custom USB Cables

LEDs & Displays

- Custom LED dot matrix or seven segment displays

- LCD Backlighting & LED light bars

- Custom LED assemblies (e.g. LED bulb replacements)

- Message Panels and Signage

Other Custom Products

- Touchscreen Integration

- High Bright Integration

- Cover Glass Integration

Custom Cable Solutions

With AGDisplays’ custom cable solutions, we allow your unique criteria to be met in the design phase of your product’s lifecycle. Customize wire criteria from wire type, length and cable configuration. Our design team works with you through every step to ensure your unit is wired accurately and to specification.

Customer Benefits

- Configuration and design created by a team of experts, saving customer time and money by sourcing from a one stop shop

- Improved efficiency for your organization including sourcing, purchasing, receiving, stocking and more

- Freight savings and global reach in supply chain

- Provides traceability off all components for quality control and assurance

- Assurance of components being integrated that are safe and compatible with your unit. Longer-lasting units and maximum performance

- Controller/kitting for developmental purposes allows customers to control the LCD module by supplying their preferred signal to the LCD controller board

- Service involves mechanical and electronic improvements

Development Kits

Get your LCD project off the ground fast with AGDisplays’ development kits for prototyping. We have a selection of the best touchscreen drivers hand-picked for increased LCD compatibility and enhanced performance. Our controller/kitting service is mainly used for developmental/evaluation purposes or finished product design solutions. AGDisplays provides pairing and sourcing cabling/interface to drive your unit.

LVDS (Low Voltage Differential Signaling)

‘LVDS’ refers to the way the data is transferred between two components, rather than a description of the wire itself. These cables run at low power, and provide very high speeds using twisted-pair copper cables. The benefit of the twisted-pair characteristic is that the configuration reduces electromagnetic radiation and crosstalk while also resisting electromagnetic interference.

LVDS cables are often provided by panel manufacturers. These cables are custom made to interface between your LCD and the control/SBC (single board computer) or the embedded mother board. They are often unusable because the PCB you are looking to connect will have a different header or your cables are the wrong length and/or the pin-outs are wrong.

TTL Cable Solutions (FPDI-1/VESA Type/DF9 Cables)

These cables are typically used with TTL display applications and are identified by the Hirose DF9 “D” shaped connector. They are compliant with VESA FPDI-1 standard. These cables provide a smooth insertion and extraction, aiding to secure connections and an easy lock mechanism.

Benefits

- Rugged overmolded design

- Flat flex (FFC) solutions

- Shielding options

- DF9 to 0.50 mm pitch FFC parts

- Round wire solutions

- Flying leads

- Adapters

Inverter/Power/LED Driver Adapters and Custom Solutions

AGDisplays provides custom backlight cables to interface between components such as panels, LED driver boards, inverter driver boards, single board computers, controllers and embedded motherboards. With various technology used across LCD panels, your design may need to add a custom adapter so to enable mating to driver boards. The only time components do not to be mated is when the panel module has a driver built in to the unit. With the help of our partners, AGDisplays can product over 10,000 unique cable designs while offering the time and experience to provide guidance and expertise where needed.

Touchscreen/Control Cables, Extension and Adaptor Cables

AGDisplays uses durable touchscreen technology with flexible offerings to meet nearly any application requirement. We open the door to a wide variety of design options by offering a wide selection of connectors, custom flex cable solutions.

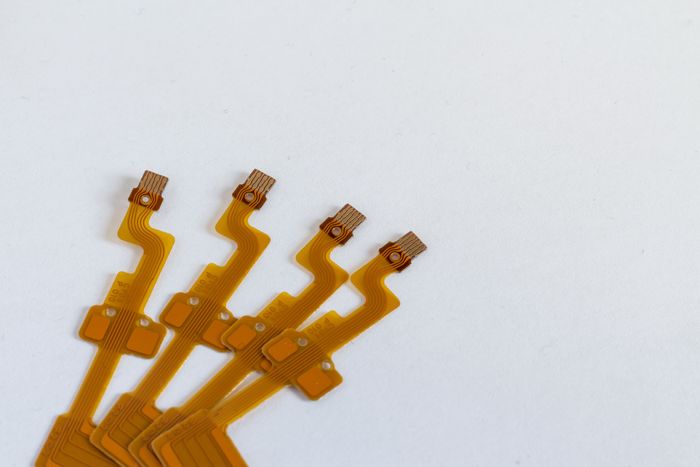

FPC (Flex Printed Circuits)

A flex printed circuit is made up of a pattern of conductive traces bonding onto a flexible substrate. They are also called flex circuits, flexible circuits, flexible pcbs. The flexible printed circuit is made up of traces of a metallic layer, bonded to a dielectric layer. The thickness ranges from <.0001 inch to >.010 inch. Though many materials can be used, often the dielectric layer is made of polyimide or polyester; and the thickness ranges from .0005” to .010”. The metal may be bonded via vapor deposition or with an adhesive.

Basic Flexible Printed Circuits

Single Sided Circuit: there is a single layer of metal traces on only one side of the dielectric layer.

Double Sided Circuit: there are metal layers on both sides of the dielectric layer. These layers may be connected by metalized thru-holes.

Multi-Layer Circuit: several copper layers are separated and encapsulated by dielectric layers; and the metal layers may be connected by metalized thru-holes.

Rigid Flex Circuits: this multi-layer circuit has some hard board layers and some flexible layers.

The advantages of this designed component is easily the expanded range of design options that the flex board gives a designer. With the ability of the board to flex to just about any shape, designs are not as limited in size and space than traditional packaging.