EMI Protection

AGDisplays adds EMI shielding into an LCD with two techniques, integrating a transparent conductive coating, or incorporating a fine conductive wire grid. Our several mesh and film solutions allow for a passive LCD installation that will not intrude on electrical components or power consumption. Our film solutions allow optimum optical performance while providing a high level of protection. Based on project guidelines and available solutions.

AGDisplays offers various EMI solutions to our customers so we can meet any specification. Level of protection is custom, based off of customer need. The film or mesh solutions are a costeffective EMI shielding solution that does not involve integrating a bulky metal box. Integration is quick and easy, requiring no redesign, allowing for fast production. Service installs new EMI shielding, or replaces existing EMI system. While our transparent film and mesh solutions are our most popular solutions, AGDisplays also offers other EMI options to meet your design requirements.

- EMI film provides the "immunity" for electronic components that are susceptible to EMI

- Typical EMI shielding enhancements involve installing a metal box to protect your equipment from interference from surrounding equipment.

- AGDisplays offers solutions for easy integration and design. Quick to create, easy to install!

- Benefit from maximizing optical performance

- Makes display/touch screen RFI compliant

What is EMI (Electromagnetic Interference)?

EMI is the disruption of operation of an electronic device when it is in the vicinity of another electronic device. Each electronic device emits an electromagnetic field;when emissions cross, it may interfere with normal operations of the electronic device.As technologies advance all around us, components in electronic systems become increasingly sensitive to electromagnetic interference. As such, integrating EMI shielding materials and measures becomes essential to the safety and reliability of your LCD and other electronics.

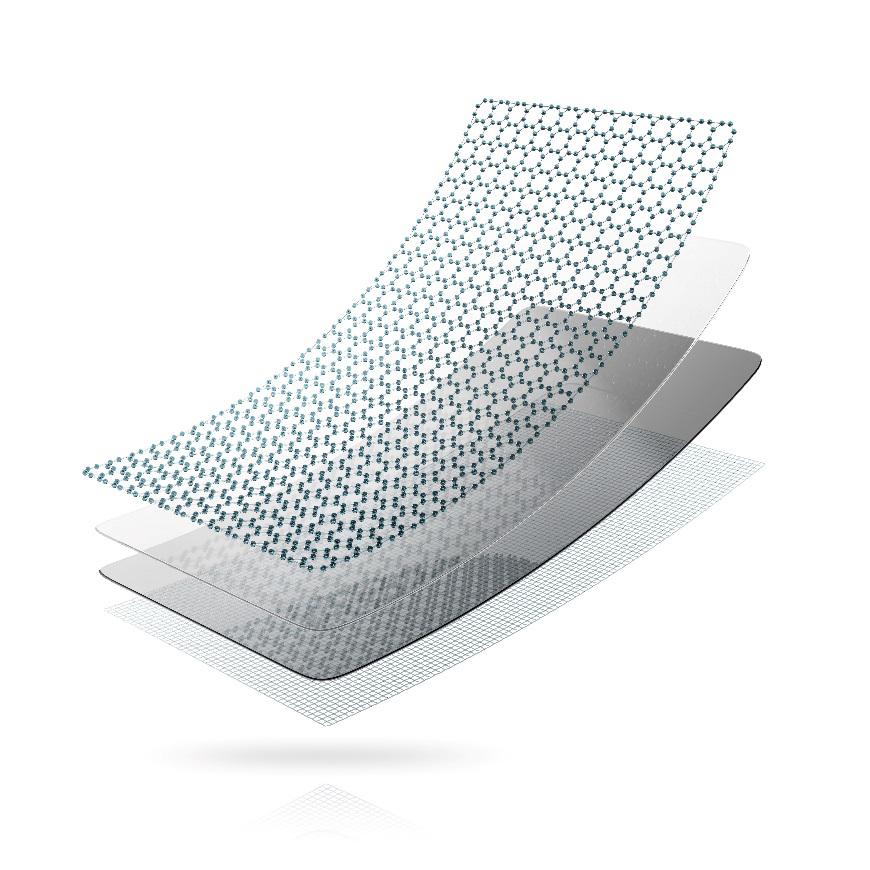

EMI TRANSPARENT THIN-FILM CONDUCTIVE COATING

Transparent thin-film conductive coatings provide LCD technology with great optical and EMI shielding properties. Some films contain layers of indium tin oxide (ITO) and metal alloy films. By increasing the conductivity of the coating, the EMI attenuation level average will increase. Typically the frequency level ranges in 100 kHz – 20 GHz. Films may be offered with conductivity ranging from 1 to 100 Ω/sq. Film solution provided for panels needing low attenuation (10-30 dB)

- Our EMI solution is a transparent conductive film

- Cost effective solution, not involving an active enhancement

- Compatible for use with a touch sensor

- High visible transmission with low electrical resistance:10 and 20 ohms/sq

- Significantly reduces problematic EMI and/or IR emissions from surface

- Superior to ITO films at low resistance for transparency & mechanical properties

Conductive Grid Mesh Solution

Conductive grid mesh solutions provide panels a high level of protection. A fine-conductive grid may be built of woven stainless-steel or copper mesh, or alternatively made with a patterned conductive metal coating on the substrate’s surface.

- Woven wire mesh

- Robust active enhancement, providing high level of protection

- Compatible for use with a touch sensor

- Photopic transmission at ≥85%

- Diffuse reflectance at 30° at ≤0.14%

- Specular reflectance at 30° at ≤1.2%

- ≤0.25 Ω/sq. surface resistance

- Shielding effectiveness: 50Mhz (megahertz):~75dB or 100Mhz:~65dB