Industrial LCD Design Services

AGDisplays offers custom LCD design services for industrial customers in the Marine, Military and Manufacturing industries. We specialize in reliable rugged design solutions for extreme environmental conditions.

What's different about AGDisplays? We meet one-to-one with your team to discuss and review your project to formulate the best design approach to meet your goals. We aim to bring you enhancing and ruggedizing designs with shorter lead times at a lower price point, while not compromising quality of components or design.

Rugged LCD Solutions

- USA-Assembled Services

- Rugged Coverglass Replacements

- Touch Screen Designs and Replacements

- Custom Logo and Designs

- Affordable Replacement LCDs

- Electromagnetic Protection

- High Bright LED Lighting for Ambient Conditions

- Enhanced Contrast and Image Clarity

- Custom Repair Programs

- High Quality Component Designs

- Lifecycle Support

- Rugged Bonding Services

- Wide Viewing Angle Solutions

- Zero Pixel Evaluations

- Heating and Cooling Management

Quality Designs and Documentation

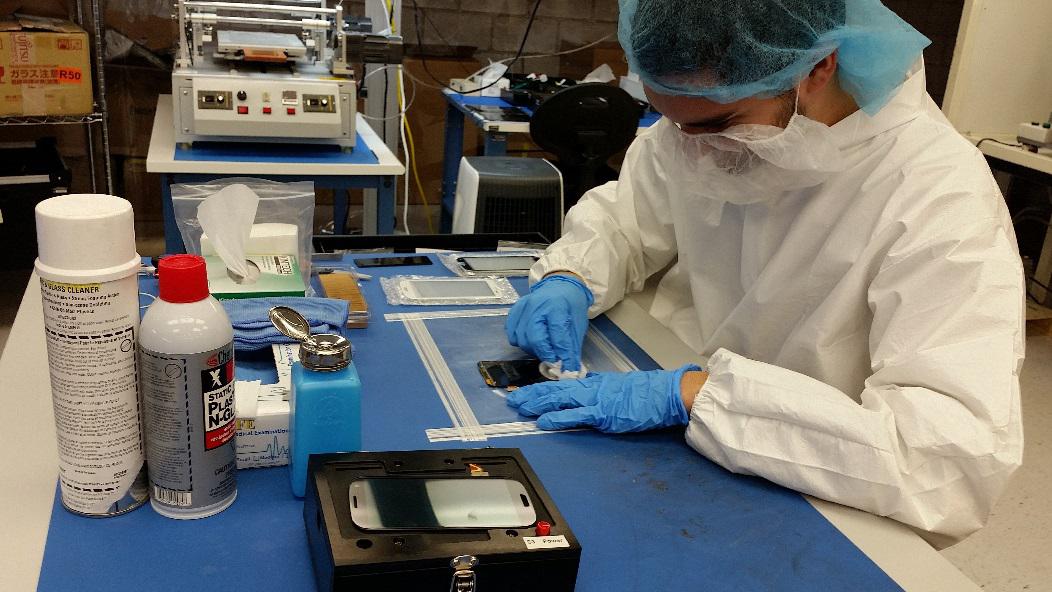

At AGDisplays, we maintain proper and accurate documentation, setting quality control standards that place AGDisplays apart from other LCD enhancement manufacturers. AGDisplays maintains rigorous quality control systems to stay compliant with today's ISO-14001 environmental standards. The proper disposal of raw components such as: cold cathode fluorescent bulbs, TFT glass, and other recyclable items are properly disposed of throughout our manufacturing process.

Our manufacturing and assembly processes are closely monitored and tracked for superior workmanship and extremely slim chance for defects. AGDisplays implements work order traveling forms that follow each unit throughout the warehouse, documenting its journey as it moves through different production stages. We structure operations so that the technicians working with your units are familiar with your project throughout the time you’re working with us.

What separates our quality procedures from the rest? Inspections are frequent and balanced with multiple evaluations between each production stage. AGDisplays performs quality control outgoing inspections on 100% of units leaving our facility for optimal quality assurance.

Why work with AGDisplays?

- Design and engineering services: high quality and readily available support

- Assistance from initial design through field startup

- Project administration and management control

- Subcontracting

- Focus on the total integrated system

- Considerable experience and skill in panel selection

- Development team that provides options based on budgets

- First article approval: quality design details and system testing for customer satisfaction

- Inspection of final solutions prior to delivery

- Quality functionality testing

- Inventoried spare parts

- Customized packaging and integration solutions for custom applications

- Control of scheduling, forecasting and logistics

- Lifecycle management: turnkey design support through life of unit

The AGDisplays Team

We have a team of trained individuals, ready to deliver high-performance display solutions to our customers. Our personnel are evaluated prior to employment and during employment on a regular basis to determine their workmanship quality exceeds the standards set by AGDisplays. Training curriculum and standards are evaluated regularly at AGDisplays by our management team.

Our Facility

- Multiple state-of-the-art Class 1,000+ clean rooms with integrated assembly lines

- Team with 25+ years of Technician and Repair Experience

- Two Oven Chambers

- Environmental Test Chamber

- Five Lines of OCA Equipment

- ESD Controlled Production Floor

- Radiometer/Photometer

- Laminating Equipment

- LCD De-laminating Equipment

- Universal LCD Test Equipment

Other Resources

- Need Affordable and Trustworthy Display Repairs? Click to read more.

- Blog Post: Mitsubishi’s LCD Departure: One Year Later

- Infographic: What is Unique About Marine Displays?

- Blog Post: Increasing Lifespan of Marine Displays

- Download: Assembly & Integration Services